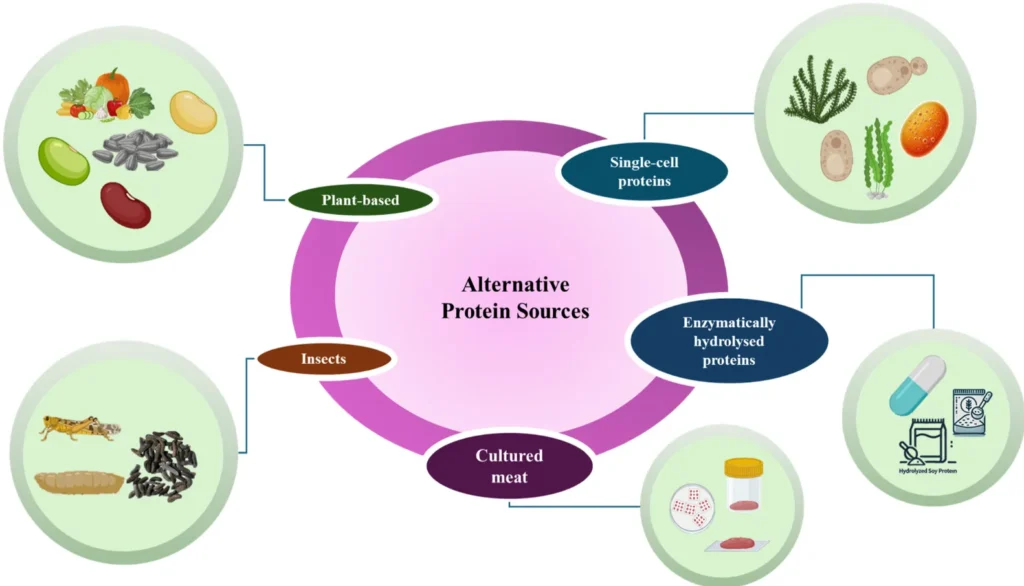

Also known as ‘novel food proteins’ or ‘plant-based meat,’ alternative proteins are composed of sequences of amino acids. They are in demand due to their sustainable production methods, which minimize Green House Emissions. In addition, they use edible insects and microbe-based inputs, which curtail the consumption of natural resources.

Technology has made it easier to accelerate the production of alternative proteins. In this article, we’ll be looking at how technology has helped transform the industry in various methods. Let’s begin.

Extrusion Helps Shape Plant Protein into Meat

In simple terms, extrusion is a process that turns proteins and plant-based ingredients into the desired shape (meat) by applying high temperature and pressure. These strict conditions break the protein structure while realigning it into a meat-like fibrous structure.

Extrusion technology also enables production to include rich ingredients, such as vitamins, amino acids, etc. This makes plant-based meat nutritious and healthier. Moreover, this allows producing products according to different consumer requirements.

The texture and tenderness are also adjusted using extrusion technology, giving the alternative protein an even better ‘meaty’ taste as required by the consumers.

The Juicy Marble filet mignon is one such example. Though it doesn’t compare to the actual mignon’s taste, the results can be used to improve the product.

Cellular Agriculture Reduces Resource Consumption

An amazing innovation, cellular agriculture is one of the pioneers in creating alternative proteins. With a centralized system, industries monitor bioreactors that produce novel food proteins from animal cells in real time.

Data is constantly fetched to keep the bioreactors stabilized and adhere to the standards set. This results in controlled emissions as well as quality produce that meets consumer demand.

However, this product isn’t considered completely vegan as it’s produced by cultivating animal cells and tissues, which are processed in bioreactors using precise and monitored benchmarks.

This is also helpful in terms of reducing the overall usage of resources as well as its impact on the environment. Traditional animal farming leads to extensive use of resources as well as biodiversity loss and an increase in greenhouse gases.

The use of cellular agriculture also aids in creating a sustainable approach to consuming abundant resources, preserving animal life, and meeting the market demands for meat produce.

3D Bio-Printing Helps Customize Production

While cellular agriculture and extrusion are used to acquire the desired produce shapes and nutrients, 3D bio-printing helps customize the products with utmost precision. Using 3D bio-printing technology, manufacturers create layered structures that mimic traditional meat in terms of texture.

Again, using design software and fiber internet connectivity (fiber ensures seamless data transmission), the detailed 3D models allow manufacturers to replicate the intricate elements of traditional meat, including fibers and texture.

The 3D bio-printing technology works closely with extrusion technology and produces replicas of actual meat from plant proteins, fats, and binders. The extrusion technology uses a printer nozzle for this matter to depose patterns.

Furthermore, this technology also enriches the final produce with the ‘meaty’ sensory experience. This makes the produce appealing to not only vegans but meat eaters as well.

The Omakase Beef Morsels and the Japanese Wagyu beef are some examples of plant-based bio-printed meat that exist in the market.

Mixed-Culture Fermentation Helps Produce Layered Flavors

Mixed-culture is the latest technique introduced with fermentation innovation, which adds desirable flavors within the depths of plant-based produce. This technique uses microbial strains with are then precisely added into layers of the meat fibers and texture.

The technique was initially introduced for plant-based dairy products, which lacked flavor profiles and nutrients. Studies have shown that mixed-culture fermentation, which includes multiple microorganisms, can result in improved sensory and nutritional value of plant-based products.

This process not only enhances the overall flavor of the meat produced but also equips the production to meet the market’s demand without compromising on quality.

What Does The Future Hold for Alternative Proteins?

The primary goal of alternative proteins is to revolutionize the food industry by producing healthier foods through sustainable options. According to the surveys conducted online, more than 50% of the consumers have deemed it difficult to accept alternative proteins, whereas enriching the produce with consumer-favored taste remains the biggest challenge.

However, with the above-mentioned technologies, the industry sees a bright future. Developments are being made especially using insect and algae-based ingredients that can easily create edible biomass mimicking traditional meat products.